To summarise the points above, the critical factors for robust self-sealing are i) availability of water or brine, ii) a minimum effective stress, and iii) sufficient clay minerals in the rock matrix (Fig. 5‑22). Points ii) and iii) relate predominantly to the swelling mechanism, which in turn may be influenced by other aspects that are briefly discussed here.

Water chemistry: It is standard practice at the Mont Terri rock laboratory to use only compressed air as "drilling fluid" to evacuate cuttings, because water-based drilling fluids are known to result in swelling and disintegration of the borehole wall. The water chemistry, or concentration of ions in the porewater (also termed ionic strength), exerts a certain control on the swelling behaviour of clays, affecting mainly the osmotic swelling (Madsen & Müller-Vonmoos 1989). However, studies on more compacted clay-rich rocks, and on the Opalinus Clay in particular, have demonstrated that salinity has a moderate influence on swelling capacity unless water with very different chemistry to the in-situ porewater chemistry (Section 5.4.3) is used (Hauber et al. 2005, Ewy 2015, Delage & Belmokhtar 2022, Favero 2017, Barakat et al. 2024), and the porewater in the Opalinus Clay is chemically buffered (Section 5.4.6). Conversely, immersion tests showed rapid swelling and degradation of the Opalinus Clay even with a balanced porewater (Seiphoori 2019a). Hence, swelling can only be prevented when non-reactive fluids are used (Ewy 2015, Wenning et al. 2021a). For this reason, non-polar, non-wetting and volatile hydrocarbons are also used for gentle sample preparation for laboratory tests.

Clay mineralogy: The more actively swelling clay minerals in the Opalinus Clay and the clay-mineral-rich confining units are the smectite-illite (Ill/Sm) interlayers, with approximately 20 – 25 wt.-% of total clay minerals. The amount of the smectite endmember is approximately 6 – 8 wt.-%, and this proportion is fairly constant in the Opalinus Clay both in the vertical direction and between boreholes and sites (Section 5.2.4). However, as pointed out by Madsen & Nüesch (1989), swelling is related not only to the activity of clay minerals but essentially to the water-accessible clay mineral surface, and therefore non-active clay minerals (e.g. kaolinite) also contribute to the process, but to a much lesser extent.

Temperature: Experiments on fractured Opalinus Clay and Callovo-Oxfordian claystone have demonstrated no significant effect on the swelling behaviour of samples heated up to 90 °C, other than the expected change in hydraulic conductivity because of viscosity change (e.g. Zhang 2013, Favero et al. 2016, Favero 2017, Gbewade et al. 2024). A temperature of 90 °C is roughly comparable to the maximum temperature that can be expected by future thermal loading in the vicinity of high-level waste drifts (Bosch et al. 2023). The maximum temperature of the Opalinus Clay in its geological history was slightly higher (just above 100 °C, Sections 4.3.5 and 4.7.4).

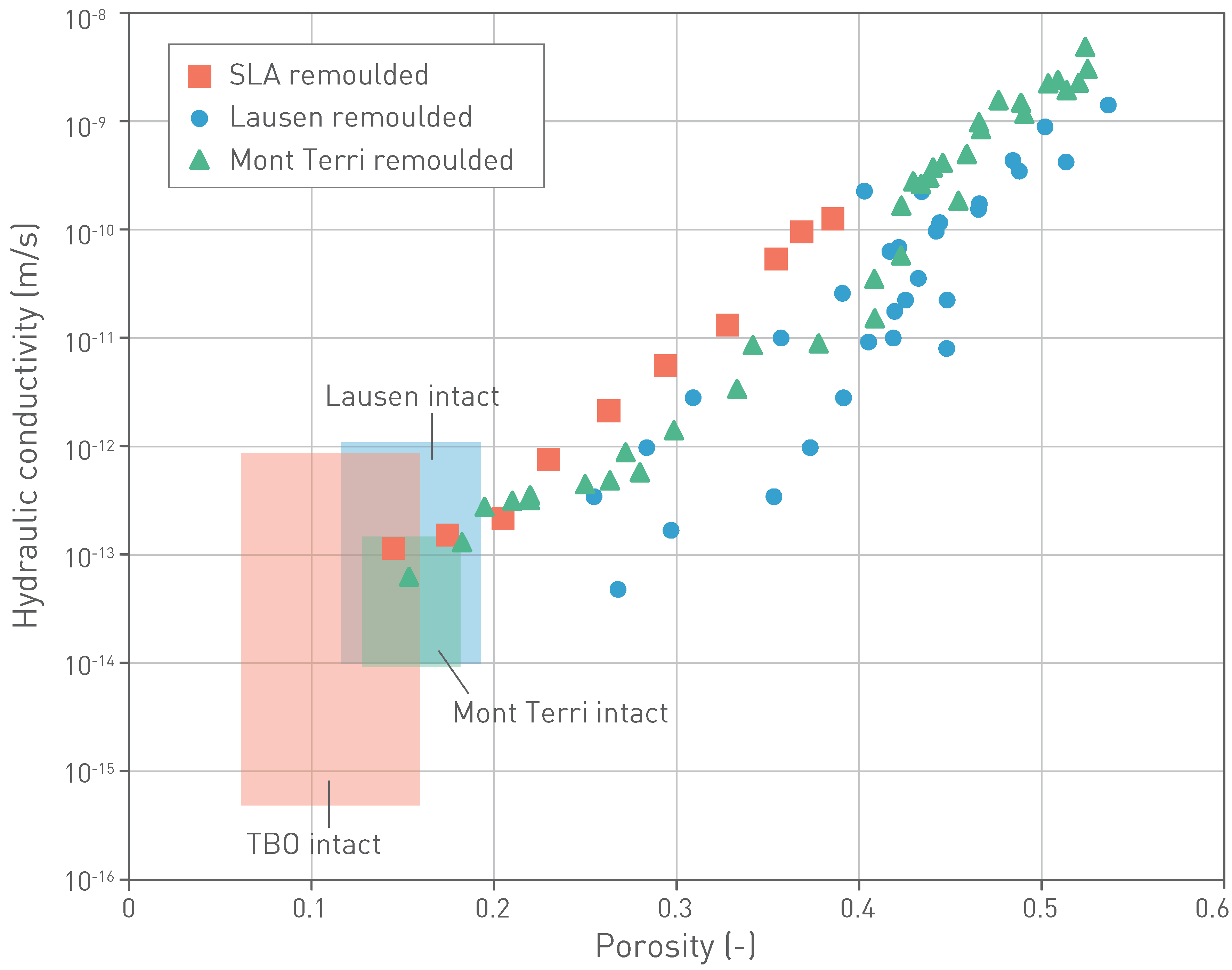

Fault gouge material: The bulk of the evidence from laboratory and in-situ tests detailed above relates to discrete fractures or displacement surfaces. Larger faults or fault zones additionally consist of variable, sometimes highly fractured and de-structured rock from mechanical wear ("fault gouge") with a higher porosity than the strongly compacted intact rock (e.g. Nagra 2002, Orellana et al. 2022). Similarly, swelling in the vicinity of fractures can de-structure the rock and lead to an overall porosity increase in the matrix (Fig. 5‑45). Laboratory tests with ground and remoulded Opalinus Clay have demonstrated swelling indexes of approximately 0.03 to 0.08, i.e. approximately one order of magnitude greater than for intact material (Fig. 5‑22; Favero et al. 2016, Crisci et al. 2019). The stronger swelling can be explained by the mechanical grinding process removing diagenetic features such as grain interlocking and bonding.

As emphasised in Section 5.7.3, swelling is associated with a local increase in porosity to compensate for the fracture-related void increase. Crushed and recompacted Opalinus Clay was also used to estimate corresponding conductivity values at different stages of compaction. These tests show very low hydraulic conductivities even at much greater (matrix) porosities than those observed in natural examples (boreholes and Mont Terri). Although the method of grinding and compacting the material and the mineralogy led to some variability, it is found that, even for a porosity of 0.30, the hydraulic conductivity remains very low (< 1 × 10-11 m/s; Fig. 5‑49). A value of 0.30 would be higher than the porosities reported for fault gouges in the Opalinus Clay at Mont Terri (< 0.23; Orellana et al. 2022, Nagra 2002).

Fig. 5‑49:Relationship between porosity and hydraulic conductivity in crushed and recompacted ("remoulded") Opalinus Clay

Individual points show results at different stages of reconsolidation (compilation after Seiphoori 2019b). Data points from Lausen cover two different tests. Rectangles show values of intact Opalinus Clay by provenance for comparison.