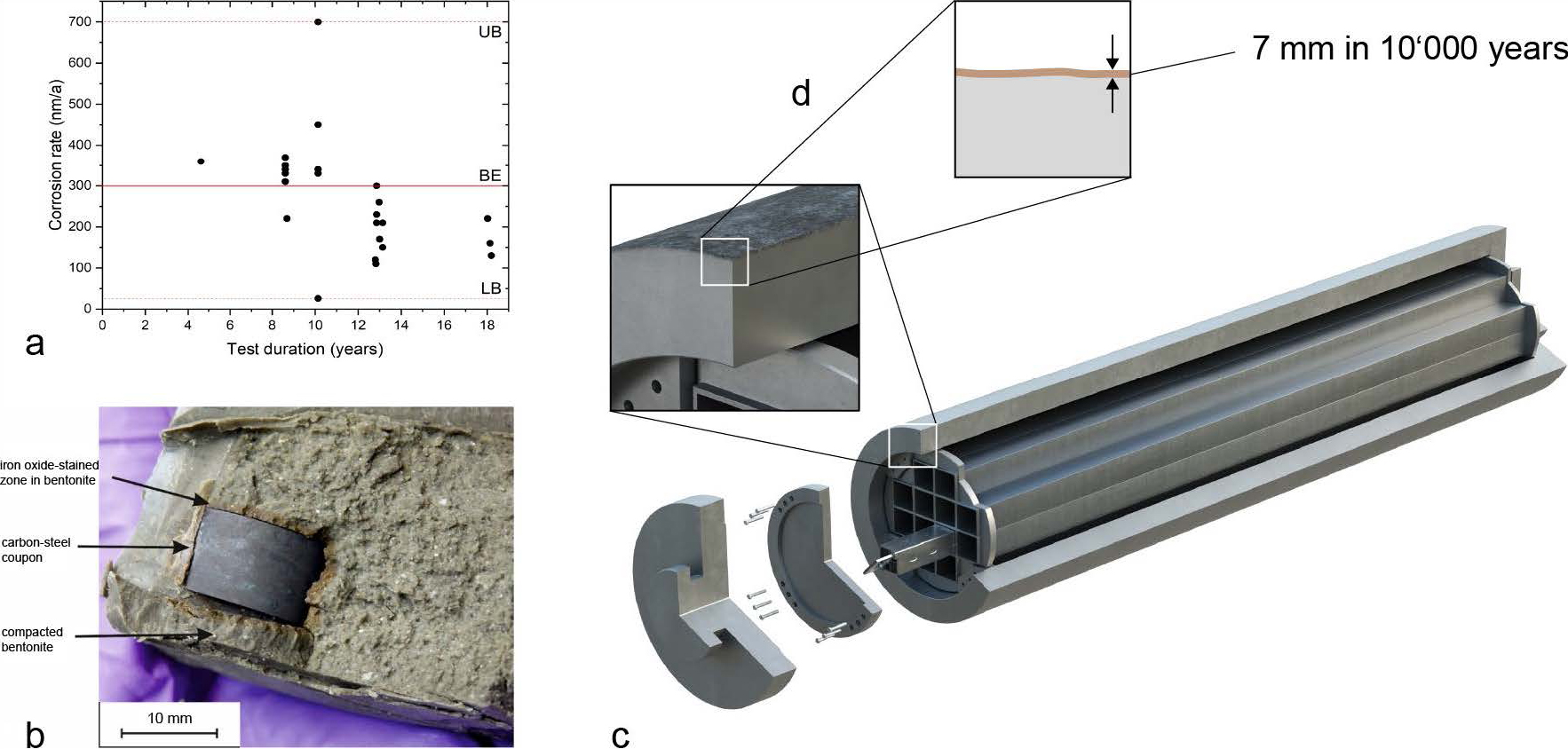

The SF and RP-HLW disposal canisters (Fig. 6‑4) provide complete containment of radionuclides for at least the early post-closure phase, when the HLW near field is exposed to distinct thermal and hydraulic disequilibrium conditions. The main arguments are that:

-

the canister has been designed such that structural integrity is ensured for at least the minimum 1,000 years required by regulations, even under the assumption of unfavourable corrosion rates, material degradation and external state conditions (Section 4.3 in NTB 24‑20, Nagra 2024d).

-

manufacturing, welding, heat treatment, inspection and handling procedures can be tailored to minimise the occurrence of undetected defects and residual stresses (Chapter 3 in NTB 24‑20, Nagra 2024d), and

-

the gas production rate due to corrosion of the canisters is limited compared with the gas storage and transport capacity of the rock and repository structures, such that excessive pressure build-up in the repository, is avoided (Nagra 2024o).

Fig. 6‑4 Illustration of a disposal canister for SF and RP-HLW. A canister lifetime of at least 1,000 years is ensured by appropriate design even under the assumption of unfavourable corrosion rates

(a) Laboratory measurements of steel corrosion rates in anaerobic bentonite saturated with artificial Opalinus Clay porewater as part of Nagra’s RD&D programme (Diomidis & Reddy 2022). (b) In-situ experiments at the Mont Terri rock laboratory confirm the low corrosion rates (Diomidis & Reddy 2022). (c) SF canister design (Nagra 2024d). (d) A corrosion depth of about 7 mm in 10,000 years under in-situ conditions is expected (Nagra 2024d).

Furthermore, the products of canister degradation (corrosion) are not detrimental to other engineered or geological barriers, because chemical interactions between corrosion products and the buffer do not significantly reduce its function as a hydraulic barrier (Section 8.2.3 and Appendix A in NTB 23-02 Rev. 1, Nagra 2024v).