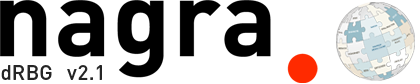

SF and its cladding

SF and its cladding, which are illustrated in Fig. 6‑2, ensure the immobilisation, retention and slow release of radionuclides. Under repository conditions, SF, which mainly consists of UO2, is chemically stable. Due to its very slow dissolution rate, it does not impair the chemical integrity of the canister or of the bentonite buffer. The main arguments supporting this claim are:

-

the SF pellets and the surrounding cladding are chemically stable and do not chemically interact with the canister and bentonite, or do so only to a very limited extent (Section 9.2 in NTB 23-02 Rev. 1, Nagra 2024v and Chapter 5 in NAB 23-10, Johnson et al. 2023)

-

the majority of radionuclides are retained within the UO2 and MOX mineral phases (Kleykamp 1985, Thomas et al. 1992, Walker et al. 1996, Johnson et al. 2023 and references therein),

-

the most rapidly released fraction of the radionuclide inventory of SF (the instant release fraction, or IRF) is small compared with the total radionuclide inventory (Section 4.2.1 in NTB 23-02 Rev. 1 Nagra 2023b and Chapter 1 in NAB 23-10, Johnson et al. 2023), and

-

following canister breaching, most of the radionuclides will be released only slowly due to limited solubility of the waste matrix and low degradation and dissolution rates after water has entered the canister (Cui et al. 2010, Ekeroth et al. 2020, Spahiu 2021, Nagra 2024v, Johnson et al. 2023 and references therein).

Fig. 6‑2:Main elements of the spent fuel that are assessed

a) Schematic view of a fuel rod, illustrating fuel pellets in Zircaloy cladding. b) Illustration of radionuclide release rates from the spent fuel following canister breaching, converted to dose rates using biosphere dose conversion factors. c) The macro and micro-structure of a fuel pellet after its irradiation. d) conceptual distribution of radionuclides in a spent fuel rod (from Johnson 2014, redrawn after Johnson & Tait 1997).

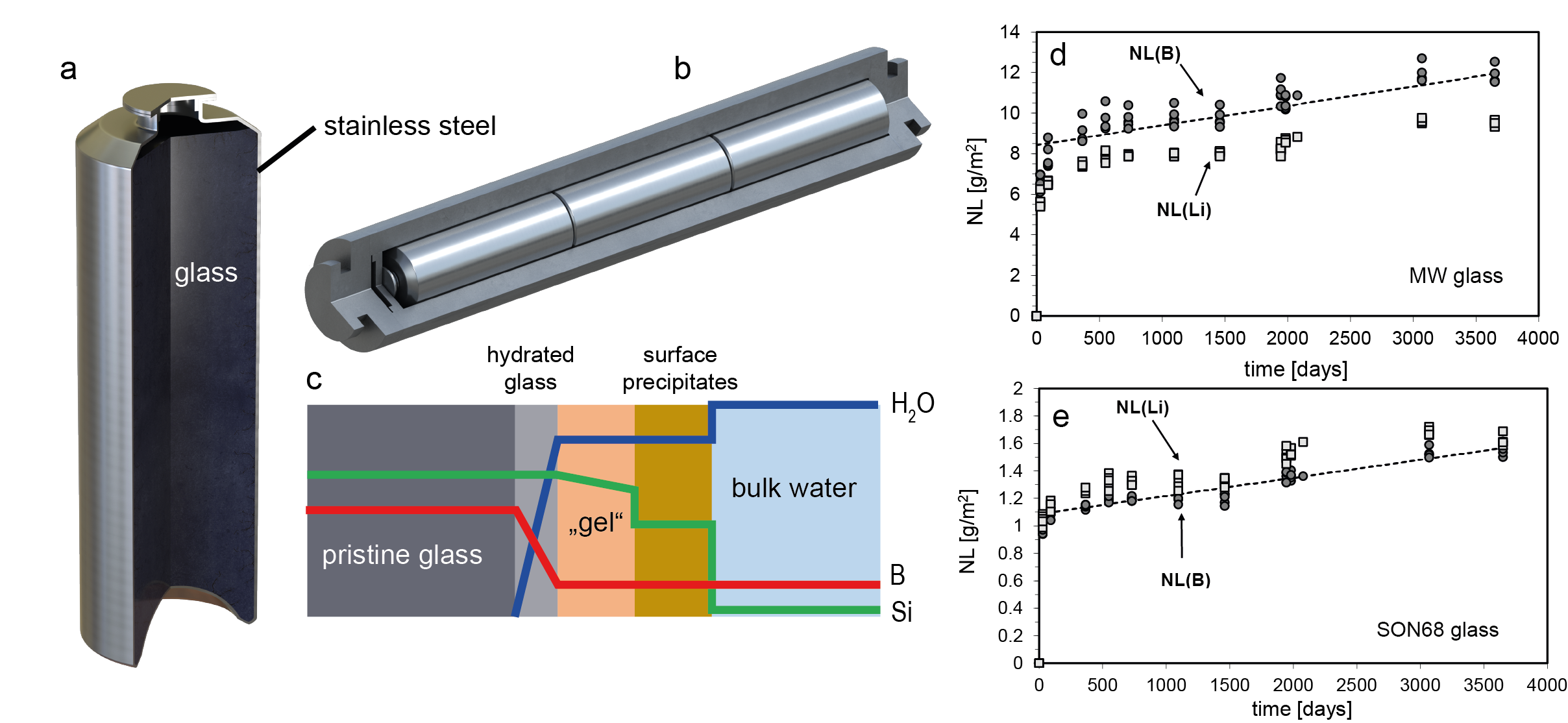

RP-HLW

RP-HLW (Fig. 6‑3) contributes to the immobilisation, retention and slow release of radionuclides. Under repository conditions, RP-HWL is chemically stable and does not impair the chemical integrity of the canister or of the bentonite buffer. RP-HLW is the product of the treatment and reprocessing of SF, which is carried out to extract fissionable U and Pu for re-use in NPPs. Research on RP-HLW has been performed for decades and has been followed by Nagra, e.g., in the scope of the NF-PRO projects (e.g., Grambow et al. 2008). Current understanding of the aqueous dissolution of RP-HLW and of the rates at which this process occurs have been synthesised in NAB 23-09 Curti (2022). The borosilicate glass matrix of the RP-HLW provides a chemical environment in which most radionuclides are immobilised and are released very slowly. This is mainly due to the chosen glass composition and to the formation of a passivation layer, which provides a barrier that protects the glass from dissolution (Gin et al. 2016, 2020a,2020b, Nagra 2024v, Curti 2022 and references therein).

The stainless-steel flasks containing the RP-HLW are compatible with the glass, the disposal canister and the bentonite, mainly due to limited chemical interactions (Section 9.3 in NTB 23‑02 Rev. 1, Nagra 2024v).

Fig. 6‑3:Main elements of the vitrified waste from reprocessing that are assessed

a) Stainless steel flask for RP-HLW. b) Disposal canister for 3 RP-HLW flasks. c) Schematic cross section through altered borosilicate glass in contact with the leaching aqueous solution, showing idealised profiles for Si, B and water concentrations. d) and e) Normalised mass loss for the non-active borosilicate glass “MW” and “SON68” glass determined from long-term experiments at PSI, Switzerland, (from Curti 2022).